SWT-WP2 Hot Air Welding Machine For SBS Bitumen 4200W

Product Despricition:

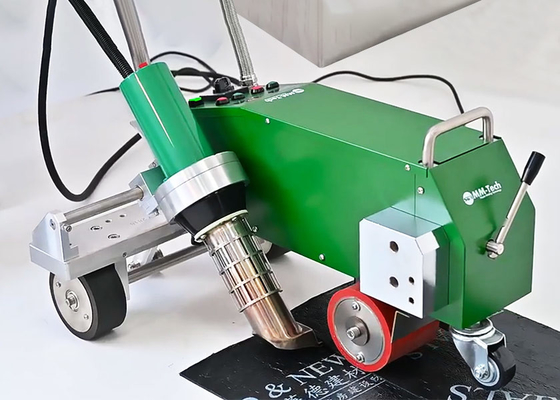

SWT-WP2 is a professional hot air welding equipment, mainly used for roof welding of polymer waterproof membranes such as PVC, TPO, CPE, EPDM, etc.

SWT-WP2 is a professional hot air welding equipment mainly used for roof welding of polymer waterproof membranes, such as PVC, TPO, CPE and EPDM. The equipment is well designed to provide efficient and reliable welding results and is suitable for waterproofing construction projects on various building roofs.

It uses high-temperature hot air to melt and bond the waterproof membrane materials together to ensure the sealing and durability of the weld. The SWT-WP2 equipment is easy to operate, equipped with an advanced temperature control system and adjustable welding speed, which can be flexibly adjusted according to different materials and construction conditions.

In addition, the equipment has good mobility and portability, making it suitable for use on various construction sites. By using SWT-WP2, construction workers can significantly improve construction efficiency while ensuring the quality and performance of the waterproof layer to provide buildings with long-lasting waterproof protection.

Product Specification:

| Model: |

SWT-WP2 |

| Application: |

SBS Situmen Welding |

| Voltage: |

230V |

| Power: |

4200W |

| Welding speed: |

1.0-10.0m/min |

| Heating temperature: |

50-620℃ adjustable |

| Welding pressure: |

200N, aaible |

| Welding seam: |

80-100mm |

| Net weight: |

36kg |

Application:

SWT-WP2 is widely used in waterproofing projects of building roofs, such as welding of waterproofing membranes such as PVC and TPO, and can also be used for welding of modified asphalt.

Product Advantages:

1. intelligent Control System:

Equipped with single-chip control system, simple and intuitive operation.

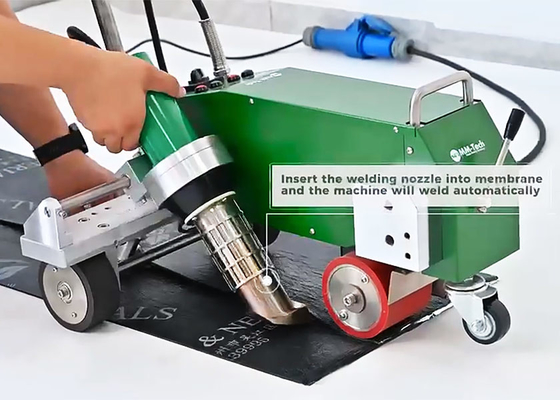

2. Welding Nozzle:

Designed with anti-scald protection to maximize heat and air volume.

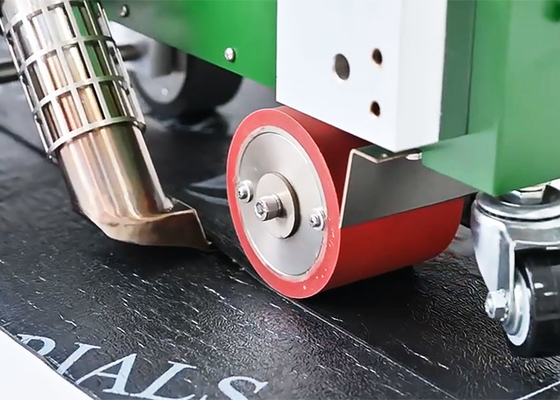

3. Pressure Roller System:

Equipped with silicone and metal pressure wheels, modified according to different SBS to maintain the quality of the weld.

4. Precision Positioning System:

The positioning system ensures that the walking is straight and without deviation.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!